TOMATO PASTE

Our Paste Types:

- Cold Break 28/30%, 36/38%

- Hot Break 28/30%, 30/32%

Packaging:

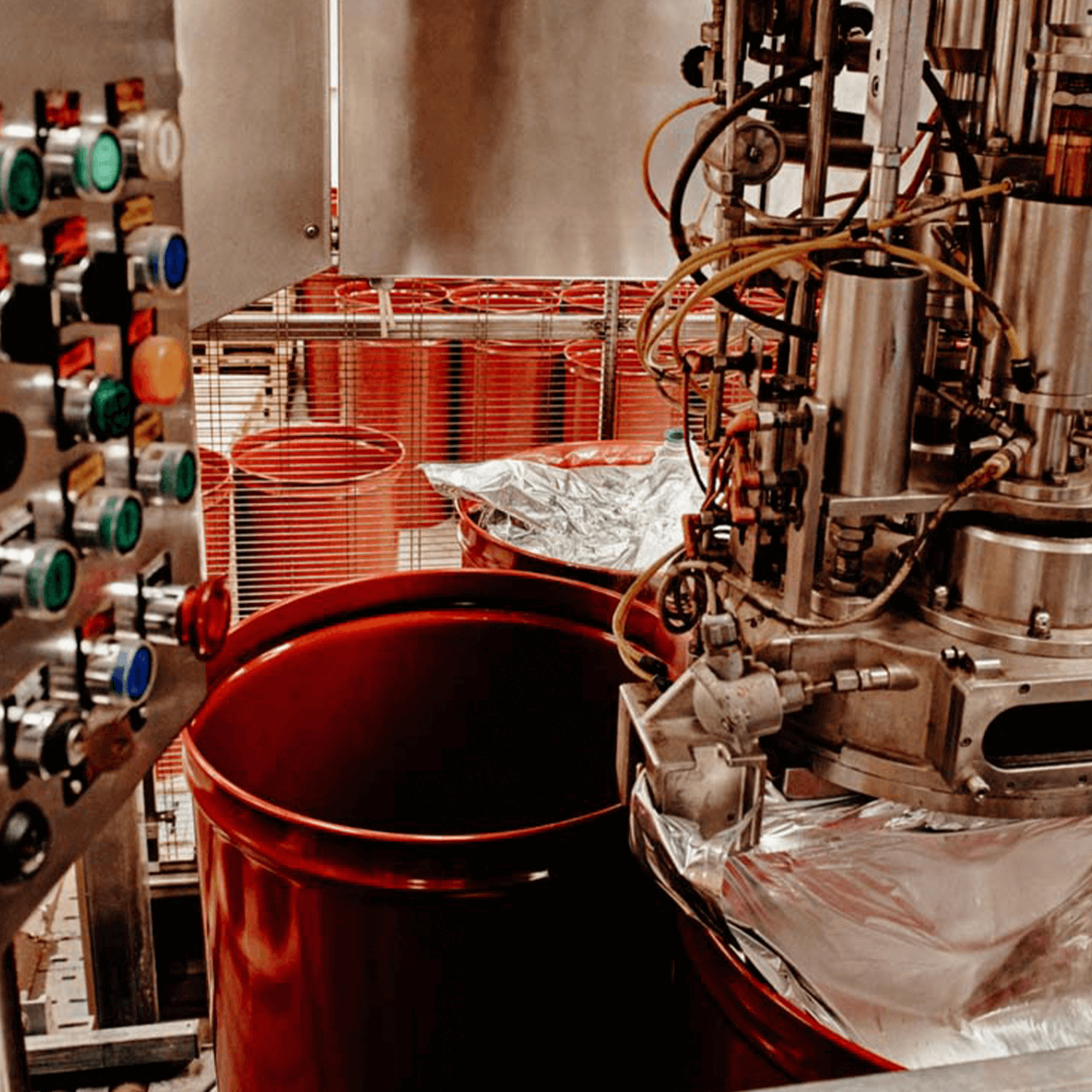

Produced tomato pastes are packaged in Barrels or BINS packages (Goodpack).

ASEPTIC DICED TOMATOES

In the production of Aseptic Diced Tomatoes, harvested ripe tomatoes are first checked at the raw material control station and those with the desired characteristics are accepted into the production process. The tomatoes that have passed are taken to the tomato pools and then they are passed through several washing operations. After going through the washing operation, firstly the small ones are calibrated and only the suitable sized ones are fed to the production line. Then, it passes through optical sorting machines and is sorted according to color. Only the good red ones pass into the process line. Then, the skins are peeled off in the peeling units, diced in desired sizes, mixed with the previously prepared tomato puree, and then diced tomatoes are ready. Just as in tomato paste production, the diced tomatoes pass to aseptic filling units, where they are sterilized and cooled, respectively, and packed under aseptic conditions.

DICED CANNED TOMATO

VARIETIES OF DICED CANNED TOMATOES

- Aseptic Diced Tomato (Cutting Size: 3/8” – ½” – 5/8” – ¾”)

- A-9 Tin Can Diced Tomato (Cutting Size: 3/8” – ½” – 5/8” – ¾”)

- A-10 Tin Can Diced Tomato (Cutting Size: 3/8” – ½” – 5/8” – ¾”)

- A-12 Tin Can Diced Tomato (Cutting Size: 3/8” – ½” – 5/8” – ¾”)

- A-9 Tin Can Peeled Whole Tomato (Cutting Size: 3/8” – ½” – 5/8” – ¾”)

- A-10 Tin Can Peeled Whole Tomato (Cutting Size: 3/8” – ½” – 5/8” – ¾”)

- A-12 Tin Can Peeled Whole Tomato (Cutting Size: 3/8” – ½” – 5/8” – ¾”)