From the partnership of 3 friends to a public offering...

THE TOMATO EXPERTS

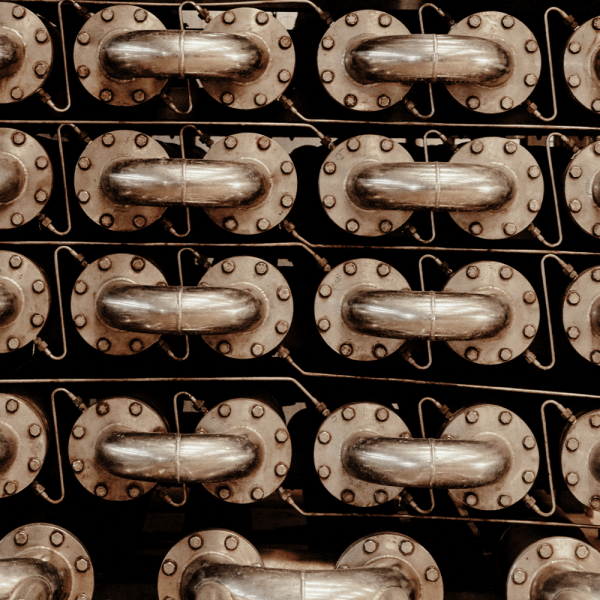

Merko was founded in 1982 by Duncan Blake, Hakkı Severge and Cemal Mersinli. Our company went public on October 6, 1994, after it proved itself especially abroad by expanding its research on tomatoes and making successful decisions. Tomato paste production started in 1995 at the Tepecik factory. In 1997, Merko decided to invest in a second tomato paste line. In 2014, the diced tomato line in Sultanköy was moved to the Tepecik factory, and a more integrated system was established. In the same year, the third tomato paste line was also invested. Always focusing on the sustainability of our product quality and making the right decisions; our company has invested in the ‘Diced and whole peeled tomato can line’ for Horeca consumption in 2021 and expanded the warehouse capacity to 3.000m2. In 2022 we have strengthened our position among tomato processing companies by buying a combined land of 64,000 m2.

- 1982 - Year of foundation

- 3400 tons- Daily capacity

OUR QUALITY POLICY

As Merko, we use our forty years of experience and knowledge to ensure that tomatoes which have become one of the most important raw materials of the world food industry, reach consumers in the healthiest way without losing their flavor.

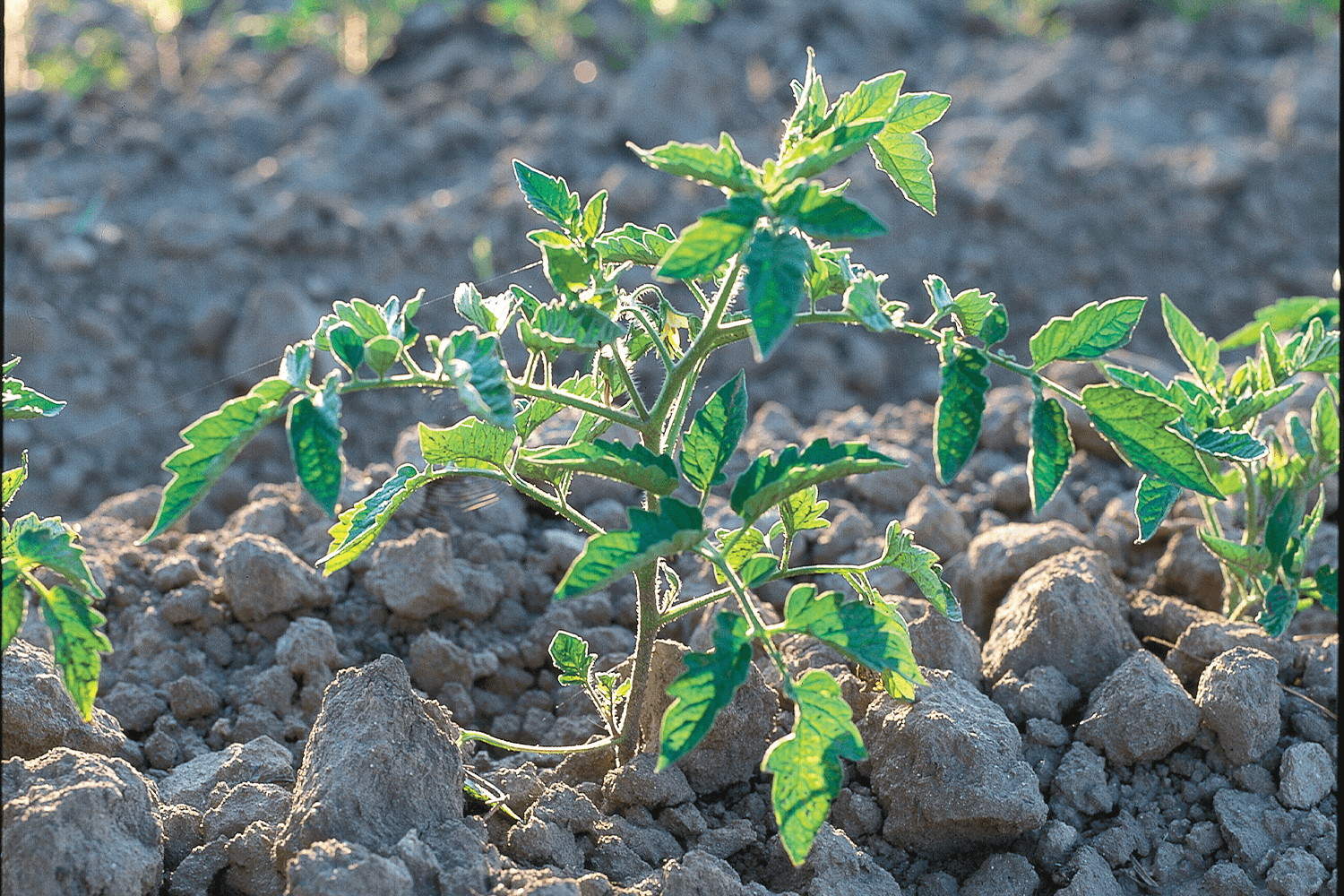

QUALITY STARTS ON THE FIELD

As Merko, our quality goal is to produce high quality, safe products at the lowest cost, fully meeting the current and future expectations of our customers. In this context, it is essential for us that all practices in Merko’s quality system comply with all applicable legal regulations and management practices.

We believe that quality and safety starts with the farmer. That’s why Merko implements a monitoring and registration process for all farmers and their fields. We use the “Unilever-initiated Sustainable Agriculture Tracking System – MUDDY BOOTS” program to monitor farmers and help improve resource management.

CONTRACTED AGRICULTURE

Merko purchases raw materials with a contracted agriculture model. Preparations for this purpose start in January-February every year and continue until the end of the harvest. First of all, according to the sales planning, a contract is made with the farmers for contract farming.

After the contracts are completed, agreements are made with seedling companies for tomato variety selection and seedling cultivation in accordance with the production plan and product types of the factory. When the seedlings reach the appropriate maturity, they are sold to the farmers and planted in the fields. In this way, in accordance with the production plan, both the selection of tomato varieties and the harvest planning are made starting from the seed selection.

REGULAR SUPERVISION

The fields belonging to our contracted farmers are monitored by the Merko Ziraat Team from plantation to the harvest of tomatoes. Professional support is provided on plant nutrition, irrigation and agricultural control. Thanks to this technical support, the supply of healthy and high-quality raw materials is guaranteed, and it is aimed to increase the field yield for the farmers. With the applied agricultural model, sustainable agricultural practices are supported.

When the harvest time approaches, field and farmer-based daily harvest planning is made in accordance with the production plan of the factory. In this way, the amount of raw material that the factory will process daily is planned and it is ensured that the raw material is processed by waiting for the least time after harvest. So, the quality of the final product is increased to the highest levels and the product’s taste is preserved.

THE MERKO EFFECT

The main factors that make Merko stand out in terms of raw materials are;

- Implementation of the contract farming model,

- Using the Sustainable Agriculture Registration System,

- Providing technical support from variety selection to harvest date,

- Processing the raw material as soon as possible by making daily harvest planning...

ENVIRONMENTAL AND HUMAN HEALTH...

One of Merko’s indispensable principles is to follow the necessary regulations for quality, hygiene and safety in all steps of the progressive food processing chain; in order to produce the safest product from seed to consumer by protecting human and environmental health.

Knowing that defining customer expectations brings continuity in quality and increases competitiveness and helps to be a leader and pioneer in the sector, Merko always attaches high value to the development and processing operations of the product and will continue to do so.

LONGEVITY OF QUALITY

Starting from seeds, Merko carefully selects all suppliers in the production process, by supervising and supporting their system developments. Merko analyzes all stages of the process with the HACCP product safety system and implements preventive practices against errors and non-conformities. It provides longevity of quality with effective corrective actions.